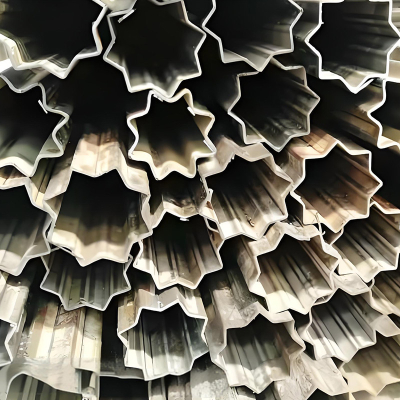

10#Seamless Cold Drawn Steel Tube

1. Uniform organization: Cold drawn seamless tubes are manufactured through cold drawing technology, which means they have a more uniform organizational structure. Compared with hot drawn seamless pipes, its grain size is smaller and its structure is denser. This uniform organizational structure gives cold drawn seamless tubes better mechanical properties and durability.

2. High dimensional accuracy: Cold drawn seamless pipes have high dimensional accuracy and can meet various demanding engineering requirements. Due to multiple passes of drawing and rolling during the cold drawing process, the outer diameter and wall thickness of the pipeline can be controlled to ensure the dimensional accuracy of the pipeline.

10 # Seamless Cold Drawn Steel Tube is a precision cold drawn seamless tube with high dimensional accuracy and good surface finish used for mechanical structures and hydraulic equipment. Choosing precision seamless pipes to manufacture mechanical structures or hydraulic equipment can greatly save machining hours, improve material utilization, and also contribute to improving product quality.

| Product Name | Carbon Steel Pipe |

| Material | A53(A.B)A106 (A. B).0345,16Mn, 10#, 20#,45# S235JR. S355JR, Q320,Q360,Q410,Q460,Q490 ASTMA252, Gr.2,Gr.3.ST37, ST42, ST52, GrB, X42 X46 X52 X5 X6 X65 X70. 30CrMo .etc |

| Wall Thickness | 2.5-75mm |

| Outer Diameter | 13.7-1219.2mm |

| Length | Length:Single random length/Double random length 5m-14m,5.8m,6m,10m-12m,12m or as customer's actual reques |

| Standard | API 5L, ASTM A53-2007, ASTM A671-2006, ASTM A252-1998, ASTM A450-1996, ASME B36.10M-2004, ASTM A523-1996, BS 1387, BS EN10296, BS ANSI B36.1 6323, BS 6363, BS EN10219, GB/T 3091-2001, GB/T 13793-1992, GB/T9711 |

| Pipe Ends | Plain end/Beveled,protected by plastic caps on both ends, cut quare,grooved,threaded and coupling,etc. |

| Surface Treatment | 1. Galvanized,bare 2. PVC,Black and color painting 3. Transparent oil,anti-rust oil 4. According to clients requirement |

| INCH | OD | API 5L ASTM A53 A106 Strandard Wall Thickness | ||||||

| (MM) | SCH 10 | SCH 20 | SCH 40 | SCH 60 | SCH 80 | SCH 100 | SCH 160 | |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | ||

| 1/4" | 13.7 | 2.24 | 3.02 | |||||

| 3/8" | 17.1 | 2.31 | 3.2 | |||||

| 1/2" | 21.3 | 2.11 | 2.77 | 3.73 | 4.78 | |||

| 3/4" | 26.7 | 2.11 | 2.87 | 3.91 | 5.56 | |||

| 1" | 33.4 | 2.77 | 3.38 | 4.55 | 6.35 | |||

| 1-1/4" | 42.2 | 2.77 | 3.56 | 4.85 | 6.35 | |||

| 1-1/2" | 48.3 | 2.77 | 3.68 | 5.08 | 7.14 | |||

| 2" | 60.3 | 2.77 | 3.91 | 5.54 | 8.74 | |||

| 2-1/2" | 73 | 3.05 | 5.16 | 7.01 | 9.53 | |||

| 3" | 88.9 | 3.05 | 5.49 | 7.62 | 11.13 | |||

| 3-1/2" | 101.6 | 3.05 | 5.74 | 8.08 | ||||

| 4" | 114.3 | 3.05 | 4.50 | 6.02 | 8.56 | 13.49 | ||

| 5" | 141.3 | 3.4 | 6.55 | 9.53 | 15.88 | |||

| 6" | 168.3 | 3.4 | 7.11 | 10.97 | 18.26 | |||

| 8" | 219.1 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 15.09 | 23.01 |

| 10" | 273 | 4.19 | 6.35 | 9.27 | 12.7 | 15.09 | 18.26 | 28.58 |

| 12" | 323.8 | 4.57 | 6.35 | 10.31 | 14.27 | 17.48 | 21.44 | 33.32 |

| 14" | 355 | 6.35 | 7.92 | 11.13 | 15.09 | 19.05 | 23.83 | 36.71 |

| 16" | 406 | 6.35 | 7.92 | 12.70 | 16.66 | 21.44 | 26.19 | 40.49 |

| 18" | 457 | 6.35 | 7.92 | 14.27 | 19.05 | 23.83 | 29.36 | 46.24 |

| 20" | 508 | 6.35 | 9.53 | 15.09 | 20.62 | 26.19 | 32.54 | 50.01 |

| 22" | 559 | 6.35 | 9.53 | 22.23 | 28.58 | 34.93 | 54.98 | |

| 24" | 610 | 6.35 | 9.53 | 17.48 | 24.61 | 30.96 | 38.89 | 59.54 |

| 26" | 660 | 7.92 | 12.7 | |||||

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible