Lemon Shape Cold Drawn Drive Shaft Tube

Material Selection:

Lemon shape cold drawn drive shaft tubes are typically made from high-strength alloy steels or specialty materials that offer the required mechanical properties for drive shaft applications.

Material selection is crucial to ensure the tube can withstand the demands of torque transmission and operating conditions.

Precision Manufacturing:

These tubes are manufactured with precise dimensional tolerances to ensure proper fit, alignment, and performance within the drive shaft assembly.

Precision manufacturing is essential for maintaining the functionality and reliability of the drive shaft system.

Application Specificity:

Lemon shape cold drawn drive shaft tubes may be designed for specific applications or industries that require unique performance characteristics, such as automotive racing, high-performance vehicles, or specialized machinery.

Product description:

The concept of a "lemon shape cold drawn drive shaft tube" is not a standard or common term in the industry. However, based on the description provided, it seems to refer to a specialized type of drive shaft tube with a unique lemon-shaped cross-section that is produced through a cold drawing process. While the specific details and characteristics of such a tube may vary, here are some general features and considerations that may apply to a lemon shape cold drawn drive shaft tube:

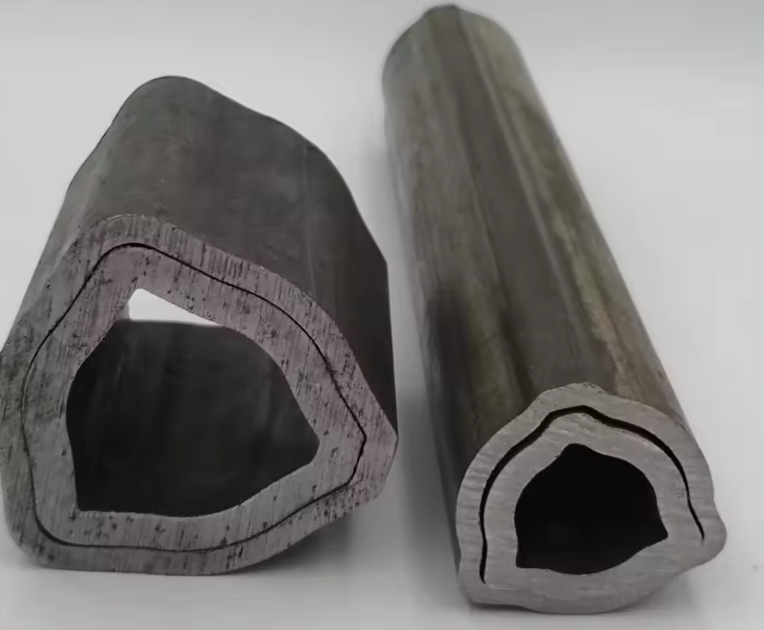

Lemon-Shaped Cross-Section:

The tube has a lemon-shaped cross-section, resembling an elongated oval with tapered ends.

This unique shape may offer specific benefits in terms of weight distribution, torsional strength, or vibration dampening properties compared to traditional round or star-shaped tubes.

Cold Drawing Process:

The tube is manufactured through a cold drawing process, which involves pulling a seamless tube through a series of dies to achieve the desired shape and dimensions.

Cold drawing imparts mechanical properties such as improved surface finish, dimensional accuracy, and strength to the tube.

Torsional Strength and Rigidity:

The lemon shape design may provide enhanced torsional strength and rigidity, which are essential characteristics for a drive shaft to transmit torque efficiently without deformation or failure.

Weight Optimization:

The unique shape of the tube may be designed to optimize weight distribution along the drive shaft, potentially reducing overall weight while maintaining structural integrity.

Weight optimization can contribute to improved performance, fuel efficiency, and handling characteristics in automotive and machinery applications.

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible