Seamless Stainless Steel Tubes for Industrial Compressor Fittings

Low carbon seamless steel pipe is generally produced by automatic pipe rolling equipment. Solid billets are inspected and cleared of surface defects, cut to the required length, centered on the perforated end face of the billet, and then sent to a heating furnace, where they are heated and perforated on a perforating machine. While perforating, it keeps rotating forward, and under the action of rollers and top head, a cavity is gradually formed inside the billet, which is called rough pipe. It is then fed into an automatic pipe rolling mill to continue rolling. Finally, the wall thickness is equalized by the equalizer and the diameter is set by the sizer to meet the specifications. It is a more advanced method to produce hot rolled seamless steel tubes by utilizing continuous tube rolling units.

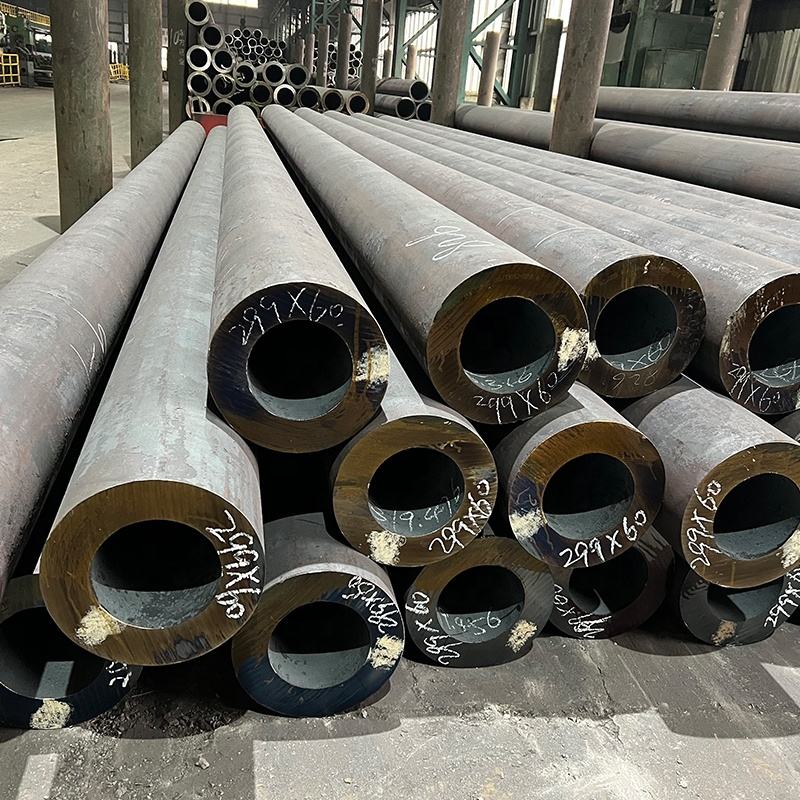

Carbon steel seamless steel pipes are made of one piece of metal and have no seams on the surface. According to the production method, seamless pipe is divided into heat pipe, cold rolled pipe, cold drawn pipe, extruded pipe, pipe jacking and so on. Carbon seamless steel pipe is mainly used for petroleum geology drilling pipe, petrochemical cracking pipe, automobile, tractor and aviation boiler pipe, bearing pipe and high-precision structural steel pipe.

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible