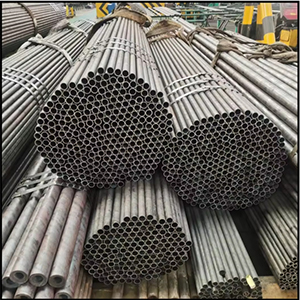

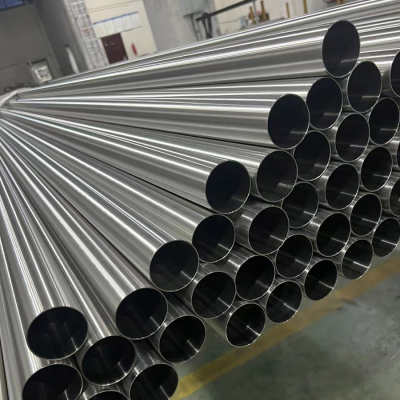

20# Low Carbon Seamless Steel Tube

Low carbon seamless steel pipe is generally produced by automatic pipe rolling equipment. Solid billets are inspected and cleared of surface defects, cut to the required length, centered on the perforated end face of the billet, and then sent to a heating furnace, where they are heated and perforated on a perforating machine. While perforating, it keeps rotating forward, and under the action of rollers and top head, a cavity is gradually formed inside the billet, which is called rough pipe. It is then fed into an automatic pipe rolling mill to continue rolling. Finally, the wall thickness is equalized by the equalizer and the diameter is set by the sizer to meet the specifications. It is a more advanced method to produce hot rolled seamless steel tubes by utilizing continuous tube rolling units.

20# Low Carbon Seamless Steel Pipe is widely used in many applications, mainly because it has the following significant advantages:

High strength and toughness: 20# mild steel has good strength and toughness, which can withstand greater pressure and impact, and is suitable for demanding structures and piping systems.

Good processability: Mild steel material has excellent cutting and welding properties, which makes it easier to process and fabricate, saving time and cost.

Corrosion resistance: Although the corrosion resistance of 20# Steel Pipe is relatively low, its durability in corrosive environments can be improved with proper surface treatment or coating.

Seamless structure: Seamless steel pipe is produced without welded joints, which makes it more uniform in withstanding internal and external pressures compared to welded pipe, reducing potential defects and weaknesses, and improving the reliability and safety of the pipe.

Excellent integrity: With no welded joints, seamless steel pipe has higher integrity and sealing, reducing the risk of air leakage and water seepage, making it suitable for use in high-pressure and high-temperature environments.

High temperature resistance: 20# steel pipe has better mechanical properties at high temperatures, able to maintain stable performance within a certain temperature range, suitable for high temperature working conditions.

Economy: Compared with alloy steel or stainless steel, 20# mild steel pipe costs less, suitable for use in projects with strict cost control.

Good heat treatability: 20# mild steel can be heat treated to improve its hardness and strength, such as quenching and tempering, which gives it better performance in different applications.

Adaptability: 20# mild steel pipe has a wide range of applications in construction, machinery, automobile and other fields, which has better adaptability and can meet a variety of industrial needs.

Environmental protection: the production process of low carbon steel is relatively environmentally friendly, which can reduce the impact on the environment and meet the modern environmental requirements.

These advantages make 20# Low Carbon Seamless Steel Pipe a popular choice in various industrial applications.