10#Hydraulic Precision Seamless Steel Pipe

1.Corrosion Resistance: Hydraulic precision seamless steel pipes are often made from materials that offer excellent corrosion resistance, such as stainless steel or alloy steel. This corrosion resistance helps prolong the service life of the pipes in harsh hydraulic environments.

2.High-Quality Material: These pipes are typically made from high-quality steel that meets specific industry standards and requirements. The choice of material is crucial to ensure the pipes can withstand the demands of hydraulic applications.

3.Tight Tolerance Control: Hydraulic precision seamless steel pipes are produced with strict tolerance control to ensure uniformity in wall thickness and outer diameter. This precision manufacturing process is essential for the proper functioning of hydraulic systems.

4.Customizable Options: Hydraulic precision seamless steel pipes can be customized in terms of size, material, and surface finish to meet the specific needs of different hydraulic applications. Customization allows for optimal performance and compatibility with hydraulic equipment.

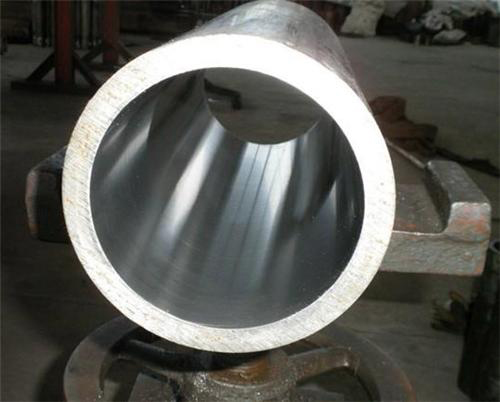

PRODUCT NAME: HONED TUBE

ALSO KNOWN AS PRODUCT NAME: HONED TUBING / CYLINDER TUBE / CYLINDER TUBING / HONED CYLINDER TUBE / HYDRAULIC CYLINDER TUBING / HONED ID TUBING

Honed tube for hydraulic cylinder is made of our factory’s own cold drawn Seamless tube (CDS tube), by honing process or Skiving & Roller Burnishing process.

PRODUCT STANDARD:

Our honed hydraulic cylinder tube is usually produced according to norms as ASTM A513, DIN 2391, DIN 1630, DIN 1629, EN10305-1, EN 10216-2, A 519, etc on customer’s request.

SIZE RANGE:

We manufacture honed tubes in metric dimensions and imperial dimensions, size range from I.D 30 mm to I.D 500 mm (1.5″ – 20″), Wall thickness 3 – 50 mm (1/8″ – 2″)

STEEL GRADES:

Manufactures Honed tubes in a wide range of carbon steel and stainless steel grades.

CARBON STEEL HYDRAULIC CYLINDER TUBING IS AVAILABLE WITH GRADES AS BELOW:

SAE 1020

SAE 1026

SAE1030/1035

E355, E255, E215, E235

ST52.3, St35, ST 52.4, St 37.4

STAINLESS STEEL HONED TUBE CAN BE SUPPLIED IN GRADES AS BELOW:

TP 304 / 304L

TP316 / 316L

TP 316Ti

Other steel grades of hone tube /honed pipe is available on customer’s request.

ADVANTAGES of HONED TUBE

High precision tolerances;

Our honed tube can meet ID tolerance H7, H8, H9, … etc according to the customer’ requirements, and its I.D dimension.

Seamless tube with high pressure resistance;

We only use seamless cold drawn tubes to produce honed pipes, which means our honed tubing can work under higher pressure, thus our honed pipes are more reliable for hydraulic cylinder applications.

High Smooth inside surface;

The roughness of our honed pipe is Max Ra 0.4 microns ID finish (16Max Ra ID Finish).

Flexible order quantity: we accept small quantity orders, even if there is only one piece of hydraulic cylinder tubing we can produce and supply.

Good weldability: The weldability of our honed steel tubing is very good, this is quite helpful for manufacturing the cylinders.

MAIN APPLICATIONS OF HYDRAULIC HONED TUBING

Honed tubing and SRB tubes (skived and roller burnished tubes) are mostly used as cylinder tube, such as hydraulic cylinder tube and pneumatic cylinder tubing, which are widely used for manufacturing and repairing hydraulic cylinders and pneumatic cylinders. As honed tube usually has very accuracy dimension tolerance and good surface smoothness, so this product is also used in applications where precision dimension or high smooth surface is need. For examples, honed tubes are suitable for various kinds of Precision Mechanical Tube, Honed Cylinder Tubing and Hydraulic Cylinder, Construct use Multi Joint Tube, Steel Axis Pipe, Injection Machine and Robotic Arm, and so on.

The feature of Precision Tube:

After cold rolling the carbon steel tube has a precision diameter, smooth surface and a best roughness.

Has an excellent performance of oil storage, can be work smoothly without pauses, and also has a longer working life.

Grade 1026 Carbon Steel Seamless Tube

Grade 1026 Carbon Steel Seamless Tubings are Medium Carbon Steel Tubings with 0.22-0.28 % carbon content with combination of 0.60-0.90 % manganese. These Tubings are most commonly used for general purpose applications worldwide. ASTM A519 Grade 1026 Tubings are ductile and strong Tubings with long wearing properties. These Tubings are manufactured as per ASTM Specification and commercially referred as carbon steel Tubings.

SAE 1026 CHEMICAL ANALYSIS

C | Carbon 0.22 – 0.28 |

Mn | Manganese 0.60 – 0.90 max |

P | Phosphorus 0.040 max |

S | Sulfur 0.050 max |

Grade C1026 Properties

GRADE | SPECIFICATION AND FINISH | SIZE RANGE | TENSILE KSI | YIELD KSI | ELONGATION % |

C1026 | ASTM A519 COLD DRAWN (CDS) | 3/8" OD- 12" OD | 75 | 65 | 5 |

ASTM A519 HOT FINISH (HFS) | 2-1/2" OD-24" OD | 55 | 35 | 25 | |

ASTM A513 TYPE 5 | 1-1/4" OD-12" OD | 85 | 75 | 10 |

Standard Length: 3 ~ 8 meters |

Standard Size of External: OD20 ~ 420mm |

Standard Size of Internal: ID18 ~ 350mm |

Material:ASTM 519 AISI 1026 or Mechanical Construction Use Pipes |

Other Specification and requirement can be customers make. |

Technique | Seamless ,DOM |

Usage | 1.hydraulic cylinder 2. automobile 3. oil drilling 4. textile machinery 5. printing machinery 6. engineering machinery |

Package | 1. Bundle packing. 2. Beveled end or plain end or vanished as buyer's required. 3. Marking: as per customer's requests. 4. Painting varnish coating on the pipe. 5. Plastic caps at ends. |

Supply | 2. cold drawn seamless steel tube 3. cold rolled seamless steel tube 4. hot-rolled steel pipe 5.hydraulic cylinder steel tube 6.DOM tube |

Carbon SAE 1026 is a general purpose grade for tubular products. CDSM allows selection of rough tube size that best suits an application or finished part by minimizing clean-up and machining time. Cold drawing produces higher physical properties without heat treating. HFS is available in larger diameters and heavier walls than cold drawn seamless. Hot finished is subject to surface imperfections and wider tolerances over CDS. DOM is cold drawn through a die and over a mandrel resulting in improved surface finish, excellent concentricity and dimensional accuracy.

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible