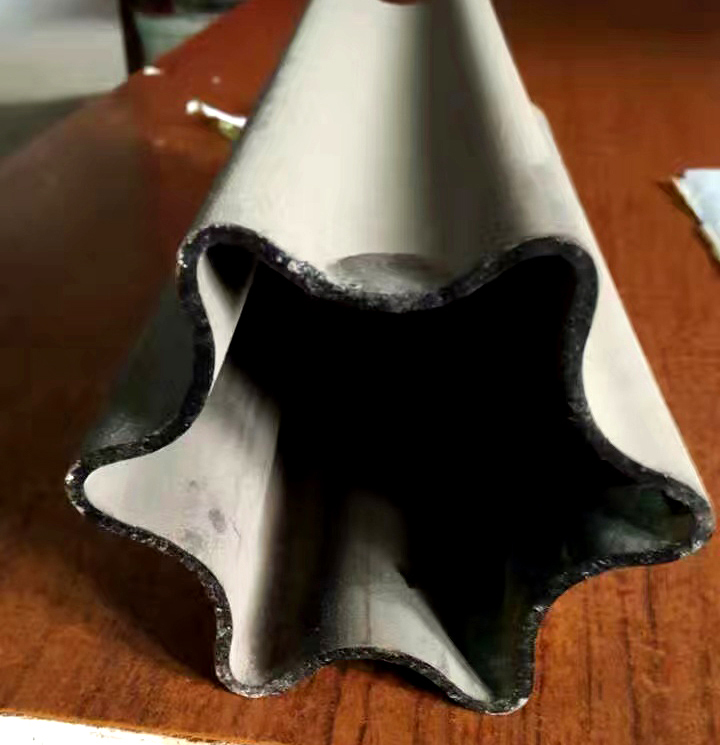

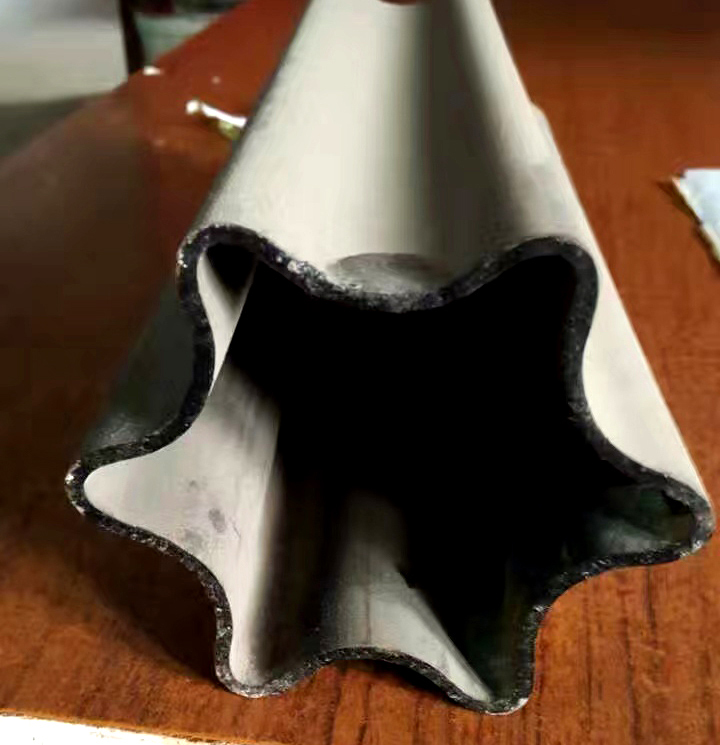

Star Shape Cold Drawn Drive Shaft Tube

Precise Dimensional Tolerances:

Star shape cold drawn drive shaft tubes are manufactured with tight dimensional tolerances, ensuring consistent and accurate cross-sectional profiles, wall thicknesses, and overall dimensions.

This precision is crucial for proper fit and alignment within the drive shaft assembly.

Seamless Construction:

Like other seamless tubes, star shape cold drawn drive shaft tubes are produced without any welded joints or seams, providing enhanced structural integrity and uniform strength along the entire length of the tube.

Material Options:

These tubes are typically made from high-strength alloy steels, such as chrome-molybdenum (CrMo) or nickel-chromium (NiCr) alloys, to meet the demanding performance requirements of drive shaft applications.

Product description:

Star shape cold drawn drive shaft tubes are specialized seamless tubes used in the manufacturing of drive shafts, particularly in the automotive and industrial machinery industries. These tubes exhibit a distinct star-shaped cross-section and are produced through a cold drawing process, which imparts unique characteristics and benefits. Here are the key features of star shape cold drawn drive shaft tubes:

Star-Shaped Cross-Section:

1,The tubes have a star-shaped cross-section, typically with 6 or more equally spaced points or "arms" extending outward from the central core.

2.This unique shape is achieved through the cold drawing process, which deforms the tube's cross-section into the desired star-like configuration.

Enhanced Torsional Strength:

1.The star-shaped design provides increased torsional strength and rigidity compared to traditional round tubes.

2.This improved torsional strength is crucial for drive shaft applications, where the tubes need to transmit high levels of torque without deformation or failure.

Improved Power Transmission:

1.The star-shaped profile enhances the power transmission capabilities of the drive shaft, allowing for more efficient and reliable power transfer from the engine or motor to the wheels or other driven components.

Reduced Weight:

1.The star-shaped design, combined with the use of lightweight alloy materials, can result in a reduction in the overall weight of the drive shaft assembly.

2.This weight reduction is beneficial in applications where minimizing unsprung weight is important, such as in automotive and industrial machinery.

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible