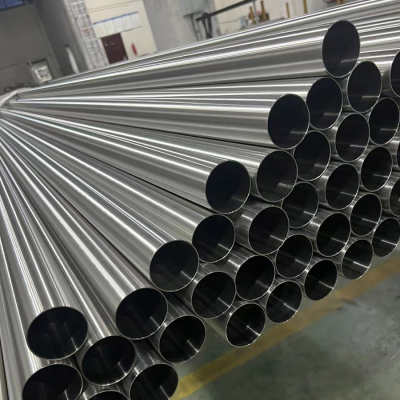

Thick-Walled Hot-Rolled Steel Pipe

Hot rolled seamless steel tubes are generally produced on automatic tube rolling units. The solid billet is inspected and cleared of surface defects, cut to the required length, centered on the pierced end face of the billet, and then sent to a heating furnace for heating and piercing on a piercing machine. In the piercing at the same time constantly rotating and forward, under the action of the roll and the top head, the internal cavity of the billet is gradually formed, known as the rough pipe. Then sent to the automatic rolling machine to continue rolling. Finally, the wall thickness is evened out by the equalizing machine, and the diameter is set by the sizing machine to meet the specifications. Utilizing continuous tube rolling unit to produce hot rolled seamless steel pipe is a more advanced method.

hot rolled seamless steel pipe process mainly includes the following steps:

Heating: The billet is heated to a high temperature (usually 1100°C-1250°C) to make it soft for subsequent processing.

Piercing: A piercing machine is used to punch a hole in the center of the heated billet to form a tubular hollow billet.

Expansion: Further deformation of the perforated billet by extrusion or rolling to enlarge the inner and outer diameters.

Finishing: Straightening of tubes after cooling to ensure uniformity in outside diameter and wall thickness and to remove surface defects.

Heat treatment: Heat treatment is carried out as required to improve the mechanical properties of the pipe.

Inspection: Ensure the quality of the pipe meets the standard through various inspection methods, such as ultrasonic inspection and pressure test.

Surface treatment: Anti-corrosion treatment on the surface of steel pipe, such as painting or galvanizing.

Thin Walled Hot Rolled Steel Pipe is mainly used as a drilling pipe for petroleum geology, cracking pipe for petrochemicals, boiler pipe, bearing pipe, as well as high-precision structural pipe for automobiles, tractors, and aviation.

Thin Walled Hot Rolled Steel Pipe, also known as thick walled steel pipe, refers to steel pipes with an outer diameter to wall thickness ratio of less than 20

Hot rolled seamless steel pipe is a kind of steel pipe with high strength and excellent corrosion resistance, which is widely used in all kinds of industrial and construction projects. The product is made by heating the steel billet to a high temperature and then forming the pipe by rolling or extruding, which is completed by cooling and straightening processes. Compared with traditional welded steel pipe, hot rolled seamless steel pipe has no weld in the manufacturing process, so it has significant advantages in strength and compression resistance.

Main features:

Excellent Mechanical Properties: As there is no weld seam, hot rolled seamless steel pipe has uniform mechanical properties and high tensile strength, which can withstand large internal and external pressure.

Good corrosion resistance: The surface treatment of the steel pipe can be selected according to demand, such as hot-dip galvanizing or painting, which enhances its corrosion resistance and prolongs its service life.

High reliability: Seamless design reduces the defects that may occur due to welding, making its performance more stable under high pressure and high temperature environments.

WIDE APPLICATION: Hot rolled seamless steel pipe is widely used in oil, gas, chemical, machinery manufacturing, building structures and other fields, and is an important basic material for manufacturing and engineering industries.

Application areas:

Oil and gas extraction: used for transportation pipelines and wellhead equipment.

Chemical industry: for reactors, pipelines and heat exchangers.

Construction: for steel structures, bridges and building support systems.

Mechanical engineering: for the manufacture of mechanical components, structural parts and heavy equipment.

Technical parameters:

Material: Q345B, 20#, 45# and other steel grades.

Outer diameter range: 21.3mm - 630mm

Wall thickness range: 2mm - 40mm

Length: conventional 6m - 12m, can be customized according to demand

Standard: GB/T 8162-2008, GB/T 8163-2018, etc.