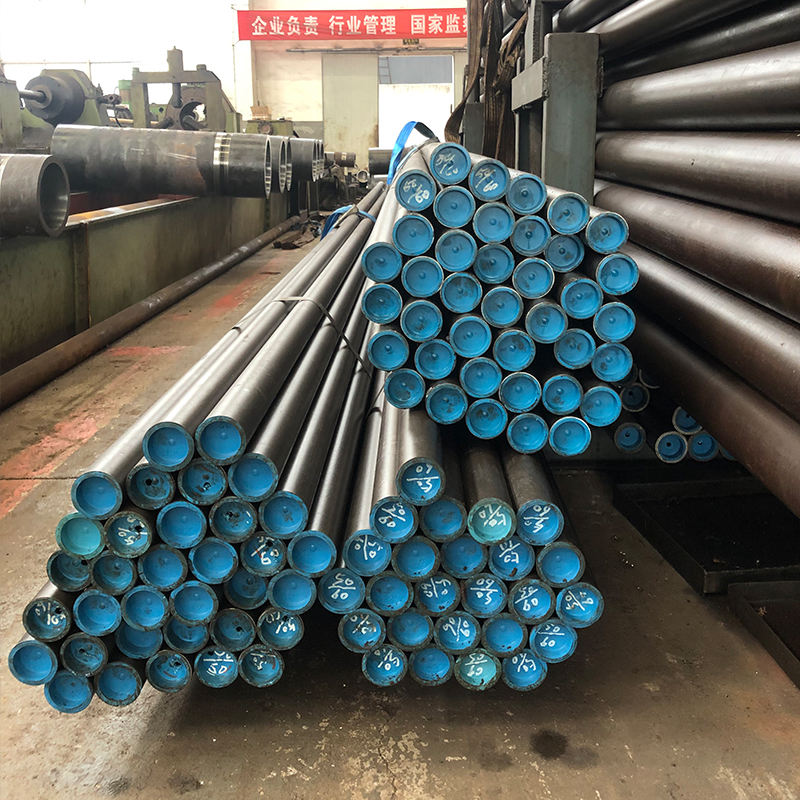

Honing tube

1.Corrosion Resistance: Hydraulic precision seamless steel pipes are often made from materials that offer excellent corrosion resistance, such as stainless steel or alloy steel. This corrosion resistance helps prolong the service life of the pipes in harsh hydraulic environments.

2.High-Quality Material: These pipes are typically made from high-quality steel that meets specific industry standards and requirements. The choice of material is crucial to ensure the pipes can withstand the demands of hydraulic applications.

3.Tight Tolerance Control: Hydraulic precision seamless steel pipes are produced with strict tolerance control to ensure uniformity in wall thickness and outer diameter. This precision manufacturing process is essential for the proper functioning of hydraulic systems.

4.Customizable Options: Hydraulic precision seamless steel pipes can be customized in terms of size, material, and surface finish to meet the specific needs of different hydraulic applications. Customization allows for optimal performance and compatibility with hydraulic equipment.

Honing cylinder barrel is a high-precision steel pipe material, which integrates the advantages of no oxide layer on the outer wall, high pressure without leakage, high precision, high finish, no deformation after cold bending, flaring, flattening without cracks, etc. It is mainly suitable for mechanical processing.

Honing cylinder barrel adopts rolling processing. Since the surface layer has residual compressive stress on the surface, it helps to close the surface micro cracks and hinder the expansion of erosion. Thereby improving the surface corrosion resistance and delaying the generation or expansion of fatigue cracks, thereby improving the fatigue strength of the honing cylinder barrel. Through rolling forming, a cold work hardening layer is formed on the rolling surface, which reduces the elastic and plastic deformation of the contact surface of the grinding pair, thereby improving the wear resistance of the inner wall of the honing cylinder barrel and avoiding burns caused by grinding. After rolling, the reduction of surface roughness value can improve the matching properties.

Rolling processing is a chipless processing. It uses the plastic deformation of metal at room temperature to flatten the microscopic unevenness of the workpiece surface to achieve the purpose of changing the surface structure, mechanical properties, shape and size. Therefore, this method can achieve the two purposes of finishing and strengthening at the same time, which cannot be achieved by grinding.

Related Products

Submitted successfully

We will contact you as soon as possible

Submitted successfully

We will contact you as soon as possible