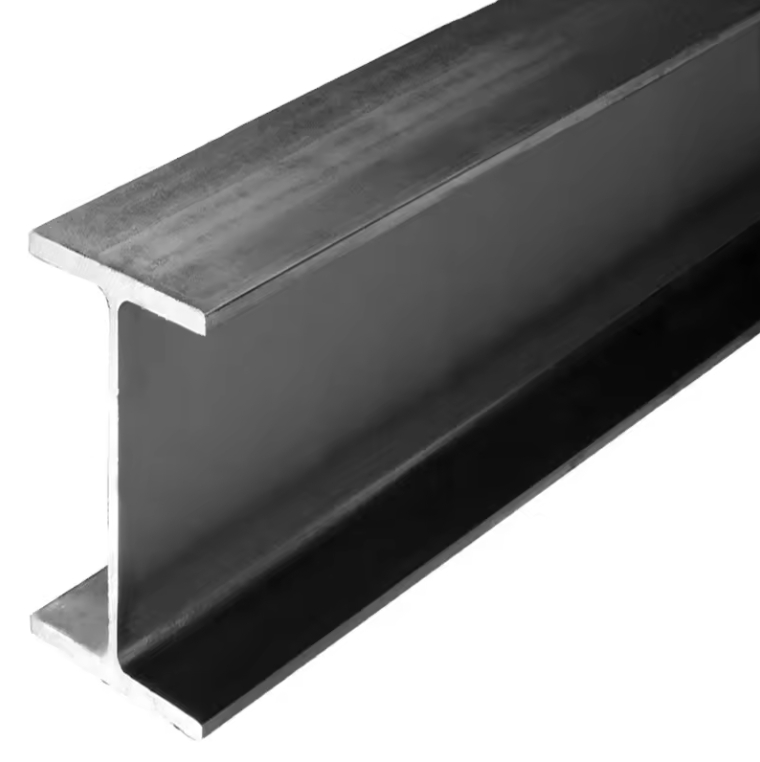

H-beam

1.Applications: H-beams are used in a wide range of applications, including buildings, bridges, cranes, industrial equipment, and vehicle frames. They are particularly useful in situations where large spans and heavy loads are involved.

2.Advantages: The H-beam's symmetrical cross-section provides several advantages, including uniform strength, ease of connection to other structural elements, and good resistance to buckling. It also has a high strength-to-weight ratio, which makes it an efficient choice for many structural applications.

3.Standards: H-beams are manufactured and tested according to various international standards, which specify the dimensions, tolerances, and mechanical properties of the beams. These standards ensure that the beams are suitable for their intended use and can be safely incorporated into structural designs.

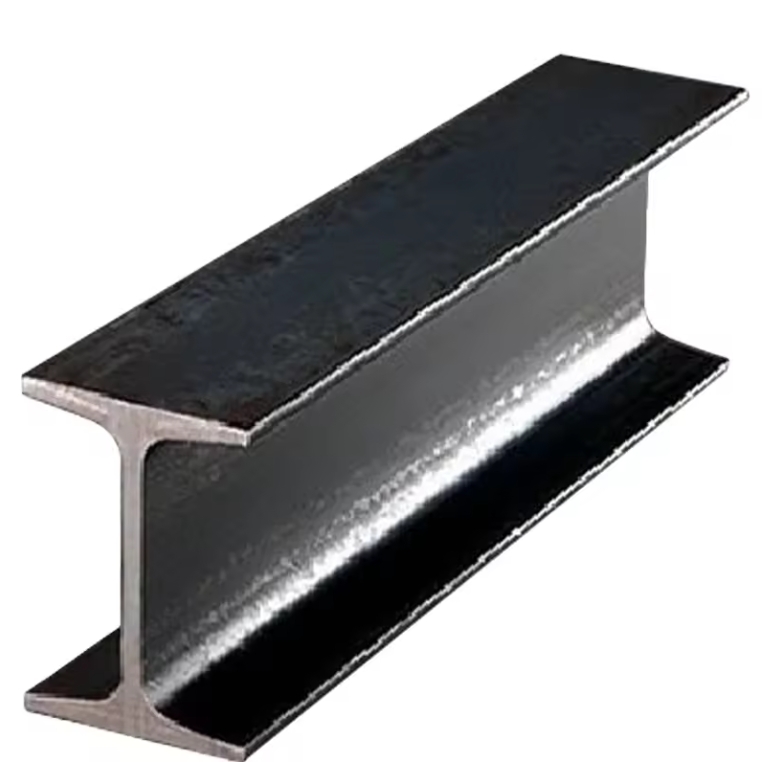

An H-beam, also known as an I-beam or universal beam, is a structural steel shape characterized by a cross-section that resembles the letter "H." It is widely used in construction and engineering applications due to its high strength, rigidity, and efficient use of material. The H-beam's design allows it to support loads primarily through resistance to bending.

Here are some key features and characteristics of H-beams:

1.Cross-Section: The H-beam has a wide, flat flange on each side of the vertical central section, known as the web. The flanges resist compressive forces, while the web resists shear forces. The width of the flanges is typically greater than the thickness, which helps in distributing the load over a larger area.

2.Sizes and Dimensions: H-beams come in various sizes, with the dimensions typically specified by the depth (height of the beam), the width of the flanges, and the thickness of both the flanges and the web. The size designation might be something like "305x305x158," indicating a beam with a depth of 305 mm, a flange width of 305 mm, and a weight of 158 kg/m.

3.Material: H-beams are usually made from structural steel, which is a type of carbon steel with specific mechanical properties suitable for construction. The steel used must meet certain standards, such as ASTM A992 in the United States or EN 10025 in Europe.

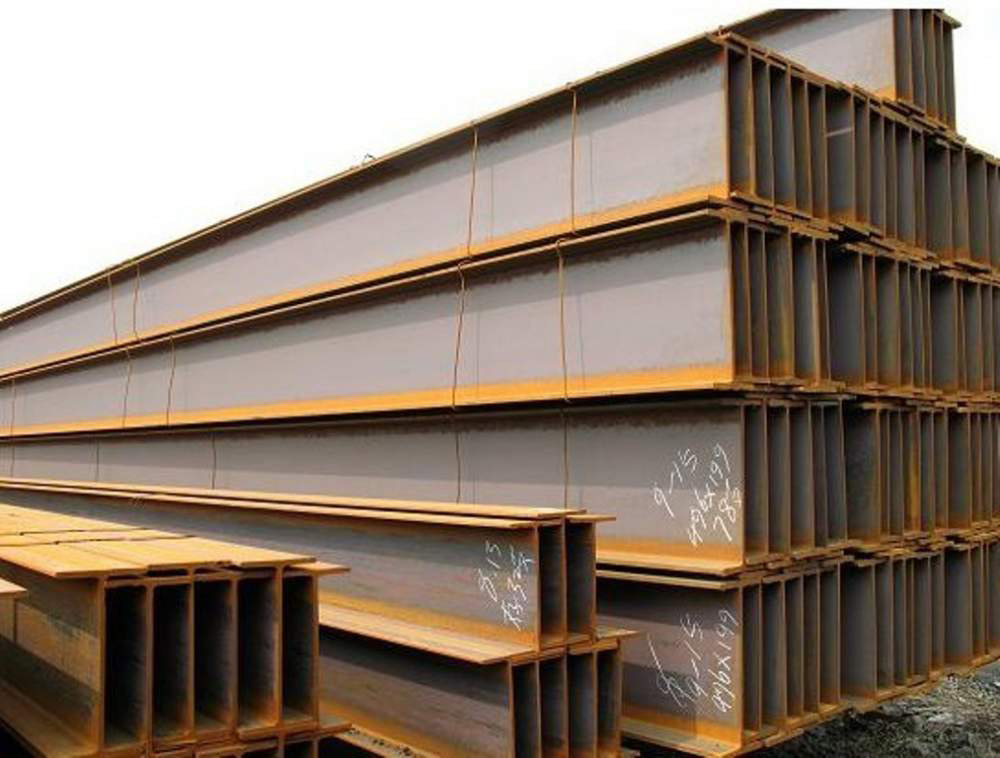

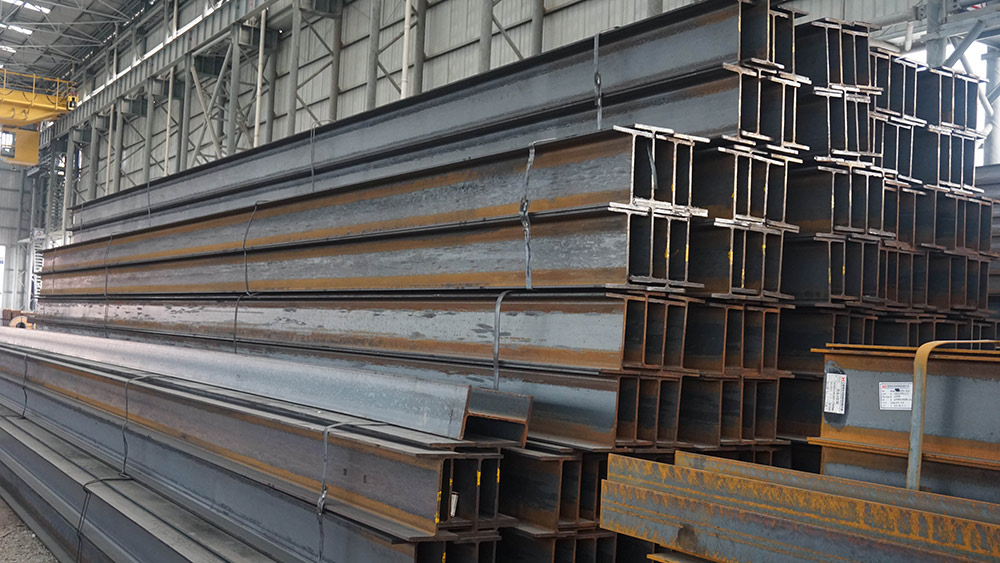

4.Manufacturing: H-beams are typically produced by hot rolling, which involves heating a steel billet to a high temperature and then passing it through a series of rollers to achieve the desired shape. Alternatively, they can be fabricated by welding together plates to create the H-shaped cross-section.